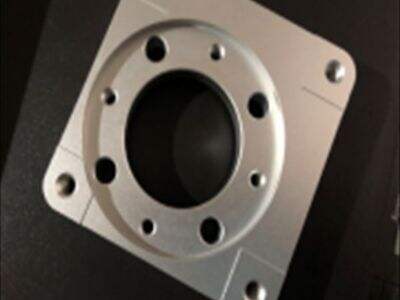

Дадатковая вытворчасць, працэс 3D друку розных тыпаў кампанент для прамысловай індастрыі. Як называецца гэтая тэхналогія? CNC фрезэрка. CNC ўскорачвае Computer Numerical Control, што значыць камп'ютары кантролююць машины, якія выра біраюць часткі. Гэтая працэдура дазваляе ствараць вельмі таячныя і часам складаныя часткі. З SHSM дапамогай гэтых супераснашчаных CNC машинаў, заводы могуць вырабляць часткі шырэй і з вышэйшай якасцю, чым з старымі, традыцыяннымі метадамі. У гэтым артыкуле мы абмяркуем перавагі CNC фрезэркі, важныя вынікі, якія ён прыносіць, што ёсць частка сучаснай прамысловай індастрыі.

Больш таячнасці і дакладнасці

Унікальная машина мае вышыню ступень дакладнасці і тэчнасці, што з'яўляецца адной з найважнейшых пераваг выкарыстання CNC-фрезеравання. Гэтыя машыны выкарыстоўваюць камп'ютарную пра gramму для кіравання рэзальнымі нейламі з экстрэмальнай дакладнасцю. Гэта дазваляе ім выра бляваць часткі, якія дужа паблізу дакладных памерыў, якія патрабуюцца. CNC-машыны, напрыклад, могуць выра бляваць часткі з дакладнасцю толькі 0.001 міліметра. Гэта малая розніца, і абсалютная розніца мае вялікае значэнне ў промысловасцях, такіх як обробка тітана CNC авіяцыйная ці пралётачная промысловаść, дзе маціць сенс атрыманне дакладных частак, што можа быць пытаннем жыцця і смерці, а таксама выконання. Таму, калі часткі фрезеруюцца з такімі дакладнымі лімітамі, гэта гарантавана, што яны будуць правільна працуваць разам.

Паднісце выдачу і зменшыце затраты на працу

Гэта толькі адна з вялікіх пераваг, які афарыруюць CNC-машынаванне; іншай перавагай з'яўляецца хуткасць вытвору частак. Яны могуць друкаваць часткі швидка і з большай таячнасцю, чым традыцыяннае вытвор, і робяць гэта набаго шырэй за традыцыыйныя спосабы праўядзення. Вытворцы магуць стварыць большую колькасць частак за меншую часіну часу завдзягода таго, як шырока працуюць CNC-машыны. Гэта значыць, што яны здатныя задавальняць патрабаванні сваіх кліентаў набаго шырэй. Прычым, CNC-машыны ў сувязі з зменшэннем затрат на працу няроўная. Ці ж гэтыя машыны былі камп'ютара-кантраліраванымі, што прыводзіць да неабходнасці меншай колькасці аперацараў для паўстаноўнага нагляду за працэсам вытвору. Гэта мінімізуе неабходнасць ручнай працы і адначасова зменшвае магчымасць чалавечых памылак падчас працы.

(3) Падвышанае аднолькавасць і аднороднасць продукцыі

Іншай прычынай, якая аб’ясняе аднолькавасць вытвораў, якія ўтвараюцца з дапамогай CNC-машын. Машыны карыстаюць камп'ютарным праграмным забезпячэннем для кіраўніцтва інструментамі рэзання, таму яны можуць вырабляць тысячы частак, якія ўсе маюць аднолькавы розмер і форму. Прысутнасць такога роду канстыянцыі ў многіх промыслах, а особліва ў аўтамабільнай індастрыі, з’яўляецца ключавай. Калі часткі не падходзяць дзяржава, яны не будуць правільна працаваць. Калі увага, якая патрабуецца, ignoruецца, гэта можа прывесці да няўдачы ў цэлым сістэмы. У Shangmeng CNC-машыны забяспечваюць, што вы атрымліваеце высокакачэственныя вытворы, на якія можна спарадніцца, бо яны вырабляюцца з високай дакладнасцю і точнасцю.

Гульне з матэрыяламі і формамі

CNC-фарма ўтрымлівае перавагу ў магчымасці працаваць з багатачайнымі тыпамі матэрыялаў. Яны працуюць з металаў, пластмас і кампаўнентамі, таму яны дужа універсальныя. CNC-машыны патрабуюць спецыялізаванага камп'ютарнага праграмнага забезпячэння, якое дапамагае ім працаваць з матэрыяламі разнай густоты, гнуткі, і твердасці. Гэта фрезераванне пластмас CNC гнутасць дазваляе вытворцам вырабляць кампаненты ў розных формах, уключна і складаных фармах, якія былі б дужа цяжкімі да здзейснення з дапамогай папярэдніх тэхналогій выраўвання. Магчымасць выраบляць часткі з розных матэрыялаў і ў розных фармах дазваляе вытворцам атрымаць выработнасць і эфектыўнасць, што прыводзіць да больш вялікага прибутку.

Навучанне CAD CAM

Нарэшце, сумлімасць CNC-обрабаткі з камп'ютарнай дапамогай у працягах дызайнавання і вытворчасці (CAD/CAM) з'яўляецца адной з найважнейшых перacam. У сутнасці, гэтае ПЗ дазваляе вытворчым кампаніям ствараць модэлі прадуктаў на камп'ютары. Дызайн можна адправіць напрамую на CNC-установкі для ўтварэння, калі толькі завяршана робата. Загрузка яго ў CAD/CAM абнаўляе швидка эфектыўнасць вытворчасці. Гэта мінімізуе колькасць памылак і захоўвае шмат часу ў аспектах вытворчасці. За счёт спрашывання вытворчасці, вытворцы могуць зменшыць час, патрабаваны для стварэння частак, дамагаячыся, каб якасць не падварыла.

Для падытожэння, CNC-обрабатка грае ключавую ролю ў сучаснай вытворчасці. Ёй прынадзеліцца большая дакладнасць і правільнасць, хутчэйшыя часы вытворчасці, больш кансістэнтныя прадукты здагоўдзенай аднолькавасці, здольнасць працаваць з рознымі тыпамі матэрыялаў і фармаў, а таксама інтэграцыя з CAD/CAM brass cnc machinin а праграмнае забеспечэнне павінна ўзмацвіць эфектыўнасць за рахунак часу цыклу, сутавых і меры якасці. Пасля каго для выработку дакладных і складаных частак неабходна выкарыстоўваць високаякасныя ЦЭН-машыны, нараджанне і праграмнае забеспечэнне. Мы прыслухоемся да таго, каб працыкаць найлепшыя рашэнні і услуги CNC-обрабаткі, каб задаволіць усе вашы промысловыя патрабаванні, гарантуючы даступленне вышэйшай якасці продуктаў кожны раз.