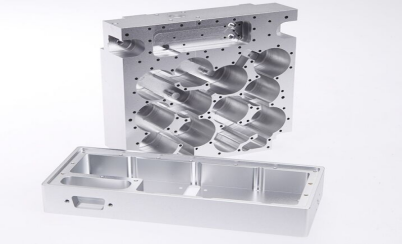

CNC milling parts are an essential component of modern manufacturing processes. With their precise and reliable operation, they play a critical role in creating high-quality products that meet the exacting standards of customers. These parts are made using advanced computer-controlled machines that can handle complex designs and geometries with ease. This allows for greater flexibility and customization in the production process.

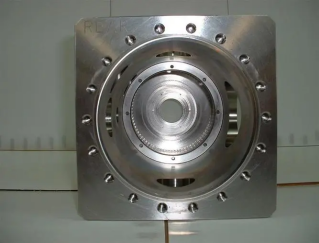

One of the key benefits of CNC milling parts is their accuracy. They are designed to tolerances that are measured in thousandths of an inch, which ensures that each part is identical to the next. This level of precision is essential in many industries, such as aerospace and medical device manufacturing, where even the slightest deviation can have serious consequences.

Another advantage of CNC milling parts is their versatility. They can be used to create a wide range of components, from simple shapes to intricate designs that require multiple operations. This makes them ideal for prototyping new products or for creating custom parts that meet specific requirements.

CNC milling parts are also highly efficient. The machines used to produce them are capable of running for extended periods of time with minimal supervision. They can produce large quantities of parts quickly and consistently, which makes them ideal for high-volume production runs.

Overall, CNC milling parts are an essential part of modern manufacturing processes. They offer precision, versatility, and efficiency that cannot be matched by other methods of production. With their advanced technology and expertise, manufacturers can create high-quality products that meet the needs of customers across a wide range of industries.

Copyright © Shanghai Shangmeng Mechanical & Electronic Equipment Co.,Ltd. All Rights Reserved - Privacy Policy