CNC milling parts are quite useful for companies that use machines and tools for the production of different types of products. These components are used to stabilize the machinery and ensure that the products produced are what consumers want to pay for. It is very important for a making business meticulous choices about the right CNC milling parts if they want to keep the operations running smoothly and efficiently. Understanding what your business needs, specifically, is an absolute must before you choose any parts.

Spend some time pondering all the types of products you create. Are they big or small? How many do you need to make per day or week? Consider too, what raw materials you typically work with to make your products. Having this knowledge means you get to choose the best CNC Milling wahi most parts beneficial towards your business and specific needs.

Checking The Precision And Quality of CNC Milling Parts

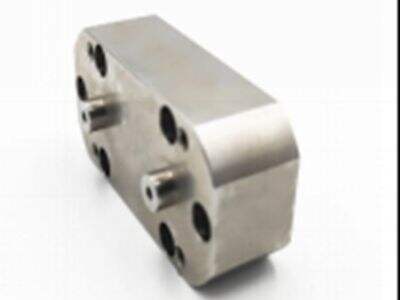

The accuracy and quality of the CNC milling parts are highly critical when searching for these parts. The parts are accurately manufactured with precise dimensions that fit together without gaps. It means that the parts are strong and well made and can withstand a pretty high-frequency use whilst using your game. So check that any CNC milling part you choose meets these important standards.

Shop for components that are built with durable surfaces and precision engineering. It is really important to pay attention to detail because it will save you from any trouble with your machines in the future, for which you might have to pay a lot, or delay the production of your machines as well.

How to Choose The Right Materials for CNC Milling Parts

How the parts are made up of also is another prominent factor that needs to ponder while choosing cnc mīkini wili pōhaku. Various materials exhibit different characteristics that can strongly influence the performance of the components in your devices. Some materials will be stronger and can take heavy use, while others are lighter and easier to manipulate but don't stand up to abuse as well.

Ask how types of products you make, and which materials will work best for them. For instance, if you produce heavy machinery components, you would need tougher materials. Well, select high-quality materials for wili cnc parts because this decision ultimately determines how good your products are and whether you will satisfy your customers or not.

Getting the Right Size and Capacity for Your CNC Milling Requirements

Size and capacity: When choosing CNC milling parts, size and capacity are also very important. The parts you use must be appropriately sized for the machines you use. If these components are too large, or too small, they don’t fit well, which results in complications in your manufacturing. A piece of the puzzle The parts' capacity -- how much they can each handle at one time -- also matters.

But, if you need to get a lot of products out in a short amount of time, you'll need parts that have greater capacity to match your production demands. With the data up until October 2023, You take time to properly measure Your machines and know how much work can be done by them at one time. Understanding this will enable you to select the appropriate CNC milling size and capacity that best suits your operations, leading to seamless operations.

7 Tips On Where To Get Your CNC Milling Parts

Now that you know what you need for your business, and what type of CNC milling parts you need, it’s time to find a good supplier. Using the parts of such a reliable and well-known supplier that they provide high-quality quality parts according to your precision and quality standard. Do not only materials but also size and capacity will give you more chances to choose, so you find the right for you a lot easier.

Choose suppliers with a good reputation in the industry and who have been in business for a long time. - In this way, you will be able to know that as long as you are getting the CNC milling parts from a trusted supplier, you will be getting the best to match your business needs. This is critical because if what you have will allow you to have the right part every time you are manufacturing your final product.

Ultimately, picking the appropriate CNC milling parts for your organization is crucial to get the job done complete and fast. Here are the most important steps to follow in order to select the best parts for your business:Understand your business requirementsConsider precision and qualityMaterial selectionSize and capacitySupplier If you follow these tips and do your research and comparisons, you will likely find the right CNC milling parts that ultimately help your business thrive. SHSM is here for your CNC milling part needs, so make sure you get in touch.