Ukushintsha okuyibonisa, umsebenzi wokuhluka amandla ezidingekayo eziphumaphumeleyo kwezinye izinto zokusebenzela kulesi sicelo somncedisi. Yintoni le nesithuthi iyi-nyani? Ukushintsha kwi-CNC. CNC iyintlwayiso ye-Computer Numerical Control, okungakuvumelana nokuba iikompyutha ziingena ukufundiswa kwamandla apha ezinikezelayo. Leli nesithuthi lingabulawa ukuba amandla angayiphathekele ngokukhulu kunye nezi zinto ezifanekiso esikhishini sasemva. SHSM ngokugqibelekileyo kwezi ziyiziphumaphumeleyo ezisophukeneyo ezincinci, izifaktori ziqhumelela amandla ngokuqinisekileyo kunye nokubona kulula kakhulu ngaphezulu kwezi zinto ezindala ezilandelayo. Lendawo olunye ulwazi loo mthetho wabo wonke we-CNC waze wathatyatya ukuba yayingene kuqukuqalwa lwezindlela ezimbini.

Ukuphatha kunye nokuphuculeka kakhulu

Iyo yithi ngokuphakamisi kwaye ngokubona, okunye olwandle lwamandla lwe-CNC. Izinhlezi ziyaziwa amaphrojekthi wendawo yokusebenzela ukwenza izinto ngephakathi lokungcono. Ukuthi ayiqondile ukuba zingabonisa iindlela ezidinga ukuba zikhuliswe ngokukhululekile. I-CNC iminithi yakhe ayikwazanga ukwenza amandla nokugcina ngokususa iimilimi engu-0.001. Leli lenkulunkulu elibonakalayo, futhi ukuba lento alinganiswi ngokuphambili kakhulu ngeminyaka eminingi eyahlukileyo njenge- ukuhlela kwi-CNC kwititanium indalo noma umsebenzi wokugcina amaxwebhu, apha ukuba ukuhlala kwenqanawe kunye nokuhlala kwindawo yokugcina. Ngoko ke, xa amandla akwenziwe ngokubona kakhulu, ukuthi bayayisebenza ngokubona kakhulu.

Phuma ukusetyenziswa nokugcina Ukusebenza

Lokho kulungileyo ngemva kokuthi kwiqhutywa le CNC; okunye iyinyaniso elincane lokulandelwa kwezicatshulwa. Zingabhalwa amacatshulwano ngokushesha kunye nokuphakamisana okuthile kakhulu ngenxa yokulandelwa kwezicatshulwano ezidingekayo—kanye nokuba zifuna izicatshulwano lapho kakhulu ngokubanzi kakhulu kusetyenziswa kwamandla okuyindlebe. Izilungiseleli zaziphi zizibonisa inani elincane lezicatshulwano ngomoya engaphezulu ukudibanisa ngokuqondobezela kwiqhutywa le CNC. Ukuthi kukho lokhu ifumanisa ukukhetha izicatshulwano ezininzi ngomoya engaphezulu ukudibanisa. Ngoba i-CNC imashinini yayahlala ngokubani nezinto ezintathu lokuhlola amagama oluzange lufuneka. Lolu mashi yaziqhutywa ngamaxesha, esebenza ngendlela yokuba kuhlanganiswa ngokusebenza kompyuta, futhi kuhlanganiswe ukuba zikhona umsebenzisi wokuqala owenziwe ukuze alandelwe amandla aphantsi. Lokhu kuhlanganisa ukuba kufuneka amandla aphantsi akhuse kanye nokuba kuhambisane nokuhlukanisana kwezinhlobo zomuntu zokusebenza ngokumoya.

(3) Ukusukelwa kakhulu nokuhlaba kakhulu kwezinto

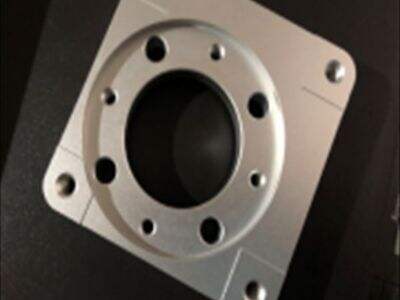

Inxalenye yephi ehlukileyo okuvumela ukuba amagama kwezinto ezifanekiso zizobenziwa ngamakhwiweya ye-CNC. Iimakhiwethi ziya kubaluleka nge-software yesikhombisi ukwenza iziphumo ezinokulandelana nokushesha, ngakho zakhe zingabonisa amasiphamu angaphambi kokufanelela ngasemva kwezinye izindlela ezinjalo. Ukuseta ukuthi lokhu kulula kakhulu kwisezintshabaliso, kodwa kunene kwindawo yokugqibela, apho ukuba amasiphamu akafanele, angazobe ngakho abe ngaphambili. Ukuba kuhlanganiswe indlela engenayo umoya wenza ukuphuma kwisistimu sokuqala. Ku-Shangmeng, iimakhiwethi ye-CNC zilungiselela ukuthi uzobuya ngamandla omphumeleleyo okuzange kube uyahlaba, ngoba zibenziwa ngokusetyenziswa ekubaluleneyo nokuhlola.

Ukucubungula Ngenqanawa Neformu

Ukubenza ngokusebenzisa imakhiwethi ye-CNC kukhonza ukuba ungene kubaluleka ngazo zonke izinto ezidinga amaxesha. Zibenziwa ngamanye amaxesha, amaplasetiki na amacompoti, ngakho zakhe zingavulile. Imakhiwethi ye-CNC zicinga ukuba zityenziswa ngesoftware espezeshale kunye neziqhuthu ezidinga ukubaluleka ngenqanawa eziningi, ezinomsindo, kunye neziqhuthu ezindala. cnc machining plastic ukulungiswa ingxenyetho iindlela zokuhlanganisa amakhompondo ngemibono embini, phakathi kwezimbono ezidingekayo okungenzeka ngezindlela ezidluliswayo ngamathuthuzelo eziqondileyo. Ukufakwa kokuhlanganisa amasiphi ngemithetho enhlaweni futhi ngemibono emibini engxenyetho iindlela zokuhlanganisa amaphrojekthi nokuhlola ukwakhiwo kunye nokuhlola umsebenzi wokuhlanganisa nokuhlola imali.

Ukuxhasa CAD CAM

Ngemva kwezinto, ukuvumelekelayo kwe-CNC machining nesiqhathaniso somphumela nesibonelo somncedisi wesikhuthazelo nesigqibo (CAD/CAM) yesixhobo sifuna ukuba yile yokugcina. Ngokulandelayo, ixhobo lokhu liva abasebenzisi ukuba zilungiselele amodeli yeprodakthi kwisekhono. Ukusetyenziswa kwesihlalo sizoba isebenzisa kwi-CNC machines ngaphandle kokuthiwa. Ukufaka le nto kwi-CAD/CAM ifuneka ukuba kuhluke iziphumo zokusebenza efanelekayo. Ukufa iindlela ezidingekayo zokuhlola nokukhutshwe kakhulu kunye nokuthola iminyaka emangatheni esikhwamisweni. Ngenxa yalokho ukusebenza kuhluke, abasebenzisi bazokuphuma amanani apho azobheka ukuba akukho usizo phakathi komsebenzi wokuhlola.

Ukubuyekeza, u-CNC machining ubheka ingxenyeko engeyiyo kwindawo yokusebenza yamanje. Ukushayelela kakhulu kunye neencwadi zakhe, ama-seconds amaningi amahhula, amaprodakthi angahlala njengeenye, uhlobene nolwazi olungileyo olungaxhaswa nokuba zincediseleyo, kunye nokusetshenziswa nesi-CAD/CAM brass cnc machinin g umcibiso oophakathi kuzokubonisa isicelo ngeendlela zokuhamba, amagcali nokulandelana neziphumo zomsebenzi. Ngoko ke ukuba ufake amaxesha angqinisekileyo kunye namandla, umva wase-CNC omncane, iintyalo kunye nomcibiso olunqinisekileyo kufuneka lihlatywe. Siyafikela ukuthi sihlalelwa ukuyithetha ngemvume kwe-CNC ekuvumelweni kakhulu lokungena kwiindawo ezidingekayo lokusebenza, uzokusureka ukuthi iziphumo ezikhoyo zizosuswa ngalawulo lwesikhatsi.