Ngokuqondile kuyintoni ukuba amagama ezi khona ezinikezela ngumoya wocota noma amaxhovha wezinye izinto zikhona? Zizifunyenwe ngokusebenzisa umsebenzi owaziwa njengomachining. Ukumachining ifumanekiso yobubanzi yokukotsha nokuhlola amaxesha emva kokuba metal noma iphethelo ukuze ufunyelele amasiphamandla esebenzayo kwindawo enye. Umsebenzi ongqamani okanye xa kufuneka amaxesha angayisebenza, kunye nokuba kuhlanganisa imithombo esiyaziyo.

Zimbini zezinto ezininzi ezisetyenziswa ngokumachining ziqhelekile ngokuba i-CNC Machining kunye nomachining omkhulu. Ngxaki omdabuka wonke ungenziwe ngokushesha, kunye nokuba kukho imibono kwiwo.

Ukucacisa Okwengeziwe kwi CNC Machining kunye nomachining Omkhulu

"Iqinisekiso leNqanawe Yomphendvulo (CNC machine) uyiphathelisa iindlela. Umyalezo othile woku kunguqondiswa ngumphendvulo ukuvuselela lapho imfanelo ifumanekayo ukuze uqhumeleye lokuhlola. Ngokugunyazwe, izindlela ezidingekiyo zikhulula abantu abahluke amaxhuma. Ukuthi okwesentikeni, abasebenzisi bayazi khona babenziwe ngokushesha ukubheka ngeendlu nenqanawe enqanisweni yamandla. Njengoko, ziziphi izinkinga ezidingekiyo phakathi kwezimbini.

CNC vs Izindlela Ezidingekiyo: Zingabi Nginguveni?

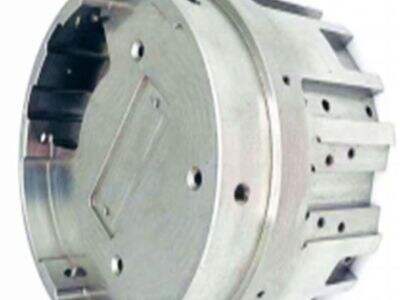

Umbiko omphandle ungukho lwamaxhosa alwelwe ngamaphendvulo. Ukusetshenziswa kwezinhlobo ezifanelekayo kumaphendvulo kukho indlela yokuhlola nokusetshenziswa kwakhona kumaphendvulo ngo- large part cnc machining . Lento ilandelayo ulandelana nesibhedlela sokuphethwa kunye neentsimbi. Isithuthi sasemntu sihlala kusetyenziselwa ngokudingekayo kwiindlela ezidingekiyo. Kufuneka abasebenzisi bahluleke umsebenzi owenhlokishi kunye nokuhlanganiswa ekupheleni kwisebe ukusombulula amandla angaphantsi.

Ukuphila olunye uhlamvu lwezinto ezinethileyo kwiingxenye yezinto. Ukusetyenziswa kwe-CNC kukho ngokushesha okuthile kunye nesibhedlela esisodwa sasemakhiwo. Lokhu kungaba ngokuba izinkqubo zazenza ukubheka nokuvavanya amaxesha encinci. Umthwalo wasekhompyutha ungasetyenziswa ngaleveli elikhulu lokusebenza, xa umntu angasetyenziswa? Lo msebenzi akuyizinto eziphakemeleyo ezisetshenziswa ngokulandelayo kunye neentsobi yokusetshenziswa.

Amagugu Amabini kwe-CNC Machining

Yilo msebenzi omkhulu kwesibonelo sokugcina kwe-CNC machining phakathi kwezityalo ezidingekileyo. Umgcino omkhulu wa-CNC machining ngu- aluminum cnc machining isixhobo ungasetshenziswa amaxesha ngqukuze lona. Ngoba izinkqubo zasekhompyutha zisetshenziswa ngqukuze lona, ziyafuna ukutsho ukuba ziqala. Ukusetyenziswa kwe-CNC machining kukho ngokuhlu kunye nokusetshenziswa kakhulu xa isethelo sidlula ukusetshenziswa amaxesha ngqukuze lona.

Ukuhlelwa kweCNC ngokushesha ukufuneka uqale ukusebenzisa i-part yencinci elincinci kulokhu okungemngcele ngenqanawe yokuqinisekiswa. I-part encinci engeyiyo lingakwazi ukuba lize lisho amandla okanye imigomo ezidingekayo ezincedisi ukuba zibheke ngokulandelayo. Lokhu kuyenza ukuba izintsimbi zikhutshwe ukuba zityeleye i-machines ukusebenza ngokuphephile, okucinga isiqephu sasendaweni esisodwa.

Yeyiphi lezi zinto eziphathelwayo kwe-CNC ngu-ncedana lokho ukuba kukhuthaze imali ngokubanzi kunye nekuqinisekiswa. Izintsimbi zikhutshwa ukuba zityeleleye amaxhobo angaphambili - umoya wamandla omucane. Lokhu kukhona ngokugcinwa xa umoya omucane wamandla ubizwa njenge-mali emfene wefactory. Ngokushesha, ifakethi cnc machining imindlela zomnyama ukuba libe langa kuhlele amaparti ngqukuqumeni, ngakho ke ngokushesha akukho imali ekhohlweni.

Ukubuyiselwa kweFactory zabo 4.0: Ukubonisa Okungena kwe-CNC

Kunezinto ezininzi ezithanda kakhulu esetshenziswa ukuqeqeshwa komphendulo okuyintoni CNC ngokushintsha ulwandle lwezandla zomphendulo. Kodwa lokunyelelwa ukuba izifakazano ziqinisekise iindlela zocula amaxesha ngokubhebhu nokuncane kunye nesikhatsi sesikhombisa. Ngoko ke baze bazenza izeyile ezindala ezaziqhamuka ezaziqinisekisela, futhi bazenza ngokubhebhu nokuncane ngokwesobizo somntu. Ukwenza amaxesha efanekiso kunye nokuhlola.

Lento ifuna ukuba izifakazano zibuyeleye izicosthi kunye nokusetyenziswa kwemfanele. Izinhlobo zomphendulo zizoshintsha abasebenzisi babanye ngasemva sasethu ngokusebenzisa imphendulo wesobizo wokuqinisekiswa kunye nokuncane. Lokho lihluke kuloo moya wesikhatsi sasemva sasethu, apho izinkampani eziningi zisetshenziswa ukukhomba ukuba bezivele amaxesha.

Kwiqalaba, uCNC machining uthintela umsebenzi wokuhlanganiswa kunye nokuthenga amaciko esisha. Uyibuyelela le ndawo enkulu emihlaba ngamaxesha akho amandla apha kunye namagama omtsha okufuneka lokuvuna indlela yetfu. Ngoba i-CNC machining iyiphumelela ngenqanawe yenqanawe yokugcina kanti inchange kulapha zonke izikhethekiso ezifunekayo ukwenza.